Unearthing ESG Value: Scalable solutions for mining projects from exploration to closure

by Michelle Gluck, Jim McKinley

View post

With electricity prices on the rise, consumers are looking for unique ways to reduce their costs of energy. Generally, there are two to three energy rates available on any given day; they include off-peak, mid-peak, and on-peak. The rates are put in effect to try to balance peak usage periods. Meaning energy is most expensive, when it is highest in demand. In attempts to combat this system, companies are charging up batteries at off-peak prices and selling the stored energy back to the grid at on-peak prices.

In fact, an increasing number companies are using large warehouses filled with batteries to store energy at low prices and sell it back at high prices to turn a profit. This tactic has many different names across the globe, the Province of Ontario, Canada this is considered a “Global Adjustment Buster” or “GA Buster”. These facilities sometimes house hundreds or even thousands of lithium ion batteries stacked on the floor and in rows throughout the facility, similar to book stacks in a library. Other larger facilities are using a “Flow Battery” technology.

One major concern for these battery facilities is the indoor air temperature. As the batteries charge and discharge energy, they also fluctuate in heat generation. Additionally, as batteries are used over a period of time, the batteries naturally degrade which is associated with increased heat generation. Therefore, the equipment and ductwork in the facility must be designed to account for the increased heat generation towards the end of the batteries life cycle. Depending on the size and application of the energy storage project, it may be of interest to increase the cooling capacity through later in the life of operations.

It is very important to try to keep these batteries a constant cool temperature as the battery effectiveness decreases with increased temperature. If the temperature of the battery increases too much, the efficiency can be significantly reduced or there can be equipment failure and risks of explosions. To maintain peak battery efficiency and to reduce the risk of the batteries overheating the performance of HVAC systems in these facilities are very important.

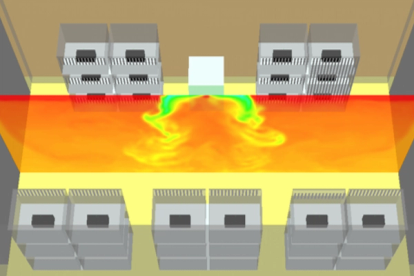

Computational Fluid Dynamics (CFD) modeling is a tool that can be used to simulate the movement of air and models the indoor temperature distribution of an enclosed area. By using multi colored models and imagery, CFD makes it clear to understand air movement and temperature distribution patterns that would otherwise be invisible. When CFD is applied to a battery housing facility, it assesses the effectiveness of the HVAC system to help maintain a specified air temperature throughout the entire battery storage space.

This image of a CFD model shows varying air velocities throughout a facility.

This image of a CFD model shows temperature variation throughout a facility. You can clearly see the HVAC system blowing cold air.

The CFD simulations consider the overall geometry of the battery storage room and include all appropriate blockage effects within the space. The volume of the space is constructed into a three-dimensional model divided into millions of grid spaces. The ventilation system components are added to the model and air flow simulations are undertaken to predict and identify any hot spots that may cause potential issues. Those issues can be identified early on in the life of the facility and can be mitigated by optimizing the HVAC system to ensure constant temperature is achieved throughout the facility.

CFD is an amazing tool with multiple applications. In this case the CFD models help to visualize temperature so owners, architects, and mechanical engineers can make informed decisions regarding the design of the HVAC system. An optimized system helps to ensure a safe, sustainable and efficient facility for the duration of its life.

by Michelle Gluck, Jim McKinley